Welcome

… to MSSC AHLE.

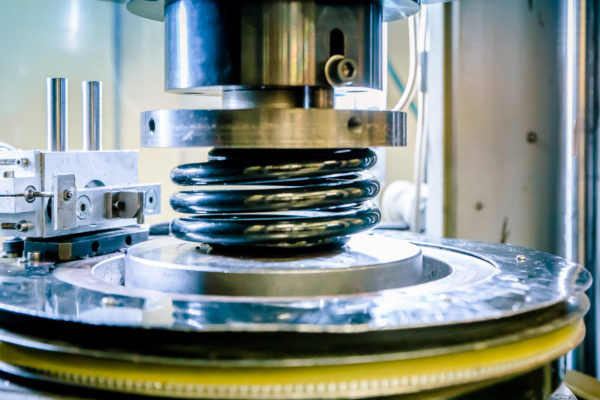

Ever since the foundation of the company in the year 1904 the success of MSSC AHLE is based on its high flexibility. Numerous innovations and further developments are the results of exactly this flexibility and adaptability. Which makes us today – over more than 100 years later – an important partner of the automotive industry and other lines of industries worldwide.