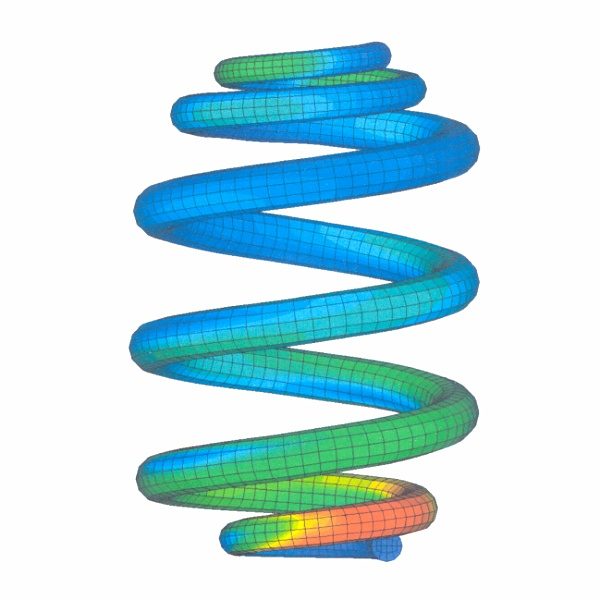

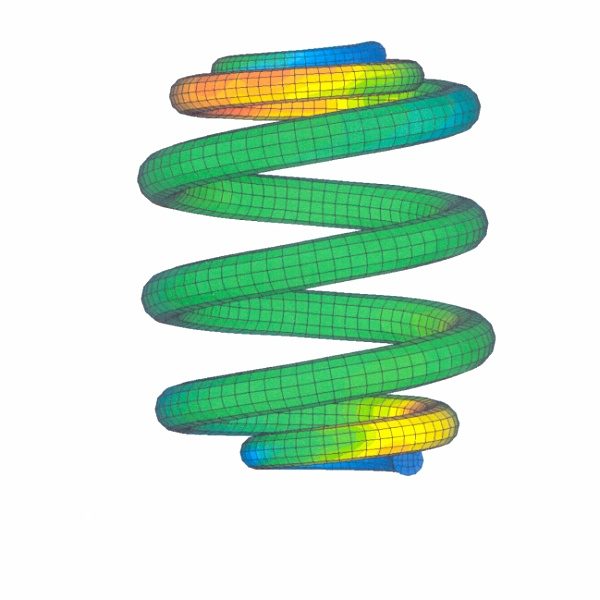

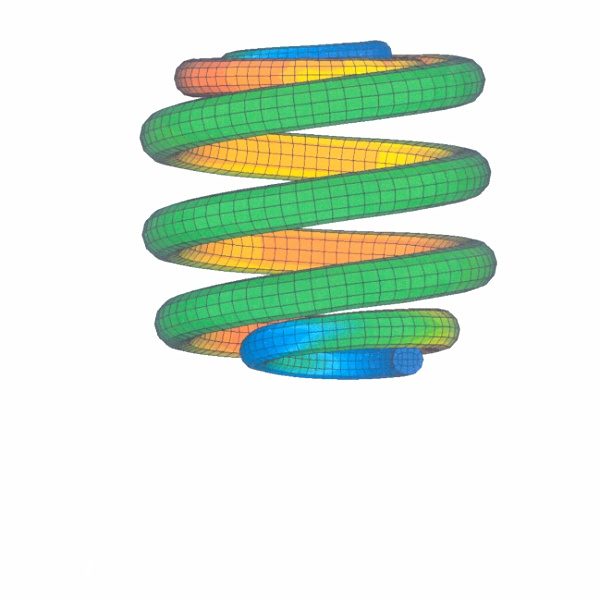

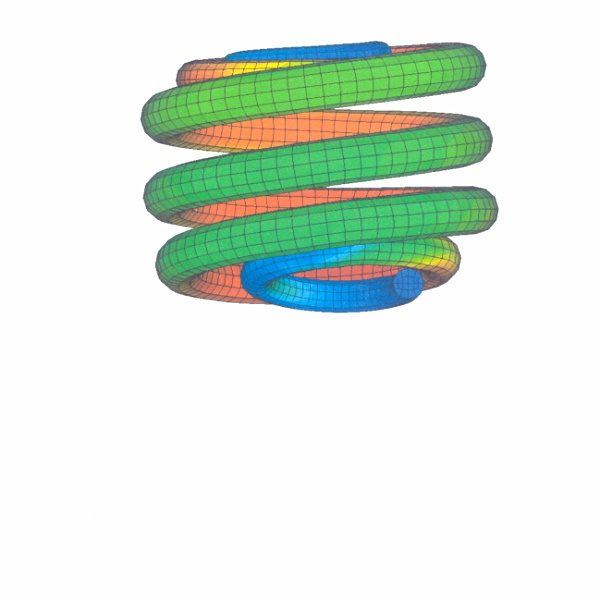

Products are developed to meet our customers’ specifications by means of an MSSC AHLE in-house spring calculation software and FEM simulations. Our core competences are both the designing and the dimensioning of springs with progressive characteristics and inconstant wire diameters. Competent development consulting in all areas related to spring application, our own tool-making department and interfaces in all conventional CAD systems complete our development services.

Spring Design

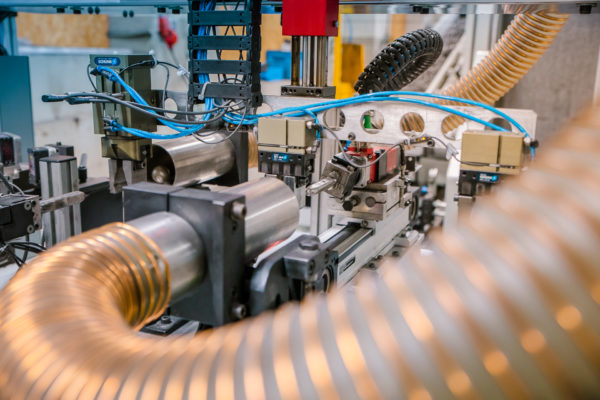

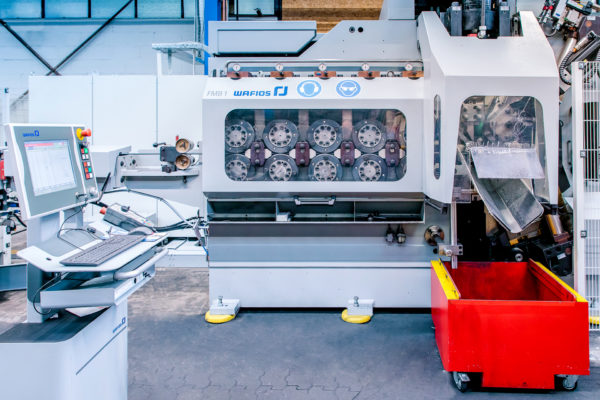

Production Process

The MSSC AHLE method of production is optimally tuned to our product portfolio and offers the perfect combination of a high automation level and a flexible manufacturing. Thanks to in-house developments, for example in the areas of bar production, NC-winders and NC-controlled setting machines, our production process is unique.

Quality without Compromises

Diligence and highest precision in all processes, from development and all stages of production through to the end product form the basis of the MSSC AHLE Quality Management System. This is the way we strive to achieve our goals we have set ourselves.

If one supplies to well-known automotive manufacturers, one simply has to prove – next to the absolute commitment to precision and reliability of his products – his flexibility all the time.

Long-time customers in this field make their highest demands on quality management. MSSC AHLE meets these requirements uncompromisingly and documents this in its certifications according to DIN-EN-ISO 9001 and ISO/TS 16949. Internal employee trainings ensure that this understanding for quality is supported throughout the company combining knowledge with practical experience.